1390 Machina secandi altae praecisionis

Exhibitio Producti

Parametrus technicus

| Area laboris | 1300*900mm | Marca Capitis Laser | Instrumenta Radii |

| Vis laseris fibrae | Ad libitum: 1000W/1500W/2000W/3000W etc. | Partes Centrales | Motor |

| Celeritas maxima sectionis | 0-40m/min | Proprietas:

| Omnino inclusus |

| Accuratio positionis repetitae | 0.02mm | Modus Operationis | unda continua |

| fons potentiae | 220V/50Hz/60Hz | motor et agitator | Motor servomotoris et rectoris Iaponiae YASKAWA / reductor Gallicus |

| Temperatura ambientis | 0-35°C | Forma Graphica Sustentata | AI, PLT, DXF, BMP, Dst, Dwg, LAS, DXP |

| Tempus laboris continuum | XXIV horae | Area Secandi | 1300*900mm, 1300*1300mm |

| Pondus machinae | 1500kg | Puncta Venditionis Clavis | Alta accuratio |

| Vita naturalis laseris | Decies centena milia horarum | Systema transmissionis | Transmissio cochleae globulariae |

| Programma Moderationis | Cypcut | Acceleratio maxima | 0.5G |

| Systema Refrigerationis | Refrigeratio aquae | Accuratio loci repetiti:

| ±0.006mm |

Crassitudo sectionis

| Parametrus Sectionis Laser | ||||||||

|

| 500W | 1000W | 2000W | 3000W | 4000W | 6000W | 8000W | |

| Materia | Crassitudo | celeritas m/min | celeritas m/min | celeritas m/min | celeritas m/min | celeritas m/min | celeritas m/min | celeritas m/min |

| Chalybs carbonicus | 1 | VIII--XIII | XV-XXIV | XXIV-XXX | XXX-XLII | XL-LV | LX-LXXX | LXX--XC |

| 2 | 3.0–4.5 | 5--7.5 | 5.5--8 | VII-IX | VIII--X | IX-XII | 10--13 | |

| 3 | 1.8–3.0 | 2.4--4 | 3.5-4.8 | 4--6.5 | 4.5–6.5 | 4--7 | 4--7 | |

| 4 | 1.3-1.5 | 2--2.4 | 2.8-3.5 | 3.5–4.5 | 4.0--5.0 | 4.2–5.5 | 4.7–5.5 | |

| 5 | 0.9–1.1 | 1.8--2 | 2.5--3 | 3--3.5 | 3.0–4.2 | 3.5–4.2 | 3.8–4.5 | |

| 6 | 0.6–0.9 | 1.4–1.6 | 1.8–2.6 | 2.5–3.2 | 3.0–3.5 | 3.0--4 | 3.3--4.2 | |

| 8 |

| 0.8–1.2 | 1.2–1.8 | 1.8–2.6 | 2.0--3.0 | 2.2--3.2 | 2.5–3.5 | |

| 10 |

| 0.6–1.0 | 1.1-1.3 | 1.4--2.0 | 1.5–2.5 | 1.8–2.5 | 2.2--2.7 | |

| 12 |

| 0.5–0.8 | 0.9–1.2 | 1.2–1.6 | 1.4--2 | 1.6--2 | 1.8--2.1 | |

| 14 |

|

| 0.7-0.8 | 0.9–1.4 | 1.0–1.6 | 1.5–1.8 | 1.7–1.9 | |

| 16 |

|

| 0.6-0.7 | 0.8–1.2 | 0.8–1.2 | 0.8–1.5 | 0.9–1.7 | |

| 18 |

|

| 0.4–0.6 | 0.7--1 | 0.8–1.1 | 0.9–1.2 | 0.9–1.2 | |

| 20 |

|

|

| 0.6–0.8 | 0.7--1 | 0.8–1.1 | 1.0–1.5 | |

| 22 |

|

|

| 0.4–0.6 | 0.6–0.8 | 0.7–0.9 | 0.8--1.0 | |

| 25 |

|

|

|

| 0.3–0.5 | 0.4–0.6 | 0.5–0.7 | |

| Chalybs inoxidabilis | 1 | VIII--XIII | XVIII-XXV | XXIV-XXX | XXX-XLII | XL-LV | LX-LXXX | LXX--XC |

| 2 | 2.4–5.0 | VII-XII | 10--17 | XVIII-XXI | XX-XXX | XXX-XLII | XL-LV | |

| 3 | 0.6–0.8 | 1.8–2.5 | 4--6.5 | VIII-XII | XII-XVIII | XVIII-XXIV | XXX-XXXVIII | |

| 4 |

| 1.2--1.3 | 3--4.5 | VI-IX | VIII-XII | 10--18 | XVIII-XXIV | |

| 5 |

| 0.6–0.7 | 1.8-2.5 | 3.0–5.0 | 4--6.5 | VIII-XII | XII-XVII | |

| 6 |

|

| 1.2-2.0 | 3.0–4.3 | 4.0–6.5 | VI-IX | VIII--XIV | |

| 8 |

|

| 0.7-1 | 1.5--2.0 | 1.8–3.0 | 4--5 | VI-VIII | |

| 10 |

|

|

| 0.8--1 | 0.8–1.5 | 1.8–2.5 | 3--5 | |

| 12 |

|

|

| 0.5–0.8 | 0.6–1.0 | 1.2–1.8 | 1.8--3 | |

| 15 |

|

|

|

| 0.5–0.8 | 0.6–0.8 | 1.2–1.8 | |

| 20 |

|

|

|

| 0.4–0.5 | 0.5–0.8 | 0.6–0.7 | |

| 25 |

|

|

|

|

| 0.4–0.5 | 0.5--0.6 | |

| 30 |

|

|

|

|

|

| 0.4–0.5 | |

| Aluminium | 1 | 4--5.5 | VI--X | XX-XXV | XXV-XL | XL-LV | 55--65 | LXXX--XC |

| 2 | 0.7–1.5 | 2.8–3.6 | VII--X | 10--18 | XV-XXV | XXV-XXXV | XXXV--L | |

| 3 |

| 0.7–1.5 | 4--6 | VII--X | 10--15 | XIII-XVIII | XXI-XXX | |

| 4 |

|

| 2--3 | 4--5.5 | VIII--X | 10--12 | XIII-XVIII | |

| 5 |

|

| 1.2-1.8 | 3--4 | 5--7 | VI--X | IX-XII | |

| 6 |

|

| 0.7--1 | 1.5–2.5 | 3.5--4 | 4--6 | 4.5--8 | |

| 8 |

|

|

| 0.7--1 | 1.5--2 | 2--3 | 4--6 | |

| 10 |

|

|

| 0.5–0.7 | 1--1.5 | 1.5--2.1 | 2.2--3 | |

| 12 |

|

|

|

| 0.7–0.9 | 0.8–1.4 | 1.5--2 | |

| 15 |

|

|

|

| 0.5–0.7 | 0.7--1 | 1--1.6 | |

| 20 |

|

|

|

|

| 0.5–0.7 | 0.7--1 | |

| 25 |

|

|

|

|

|

| 0.5–0.7 | |

| Aes | 1 | 4--5.5 | VI--X | XIV-XVI | XXV-XXXV | XXXV--XLV | 50--60 | 70--85 |

| 2 | 0.5--1.0 | 2.8–3.6 | 4.5–6.5 | 10--15 | 10--15 | XXV-XXX | XXX-XL | |

| 3 |

| 0.5--1.0 | 2.5–3.5 | 5--8 | VII--X | XII-XVIII | XV-XXIV | |

| 4 |

|

| 1.5--2 | 3.5-5.0 | 5--8 | VIII--X | IX-XV | |

| 5 |

|

| 1.4-1.6 | 2.5–3.2 | 3.5-5.0 | VI-VII | VII-IX | |

| 6 |

|

|

| 1.2--2.0 | 1.5–2.5 | 3.5–4.5 | 4.5–6.5 | |

| 8 |

|

|

| 0.7-0.9 | 0.8–1.5 | 1.6–2.2 | 2.4--4 | |

| 10 |

|

|

|

| 0.5–0.8 | 0.8–1.4 | 1.5–2.2 | |

| 12 |

|

|

|

|

| 0.6–0.8 | 0.8–1.5 | |

| 16 |

|

|

|

|

|

| 0.6–0.8 | |

Partes Principales

Applicatio

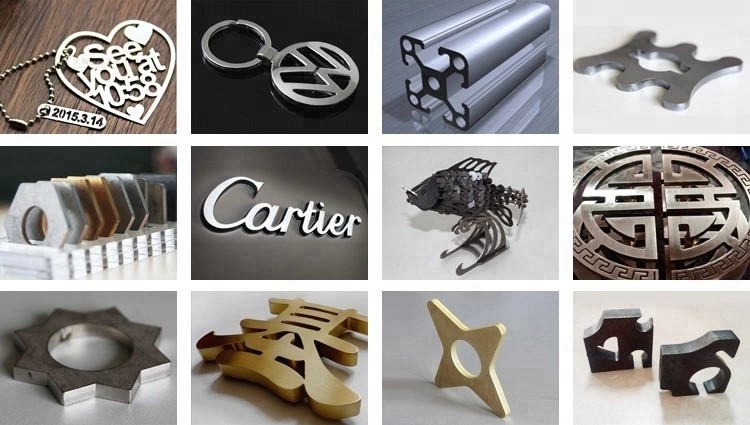

Industria applicationis:

Machinae secandi lasericae altae praecisionis 1390 late adhibentur in fabricatione tabularum publicitariarum, inscriptionum, signorum, inscriptionum publicarum, litterarum metallicarum, litterarum LED, supellectilis culinariae, litterarum publicitariarum, tractationis laminarum metallicarum, partium et componentium metallorum, ferramenta, chassis, tractationis pluteorum et armariorum, artificiorum metallicorum, supellectilis artisticae metallicae, sectionis tabularum elevatorum, ferramentarum, partium autocineticarum, cornicium vitrorum, partium electronicarum, laminarum nominum, etc. Curant ut quam primum operari possit durante processu sectionis lasericae.

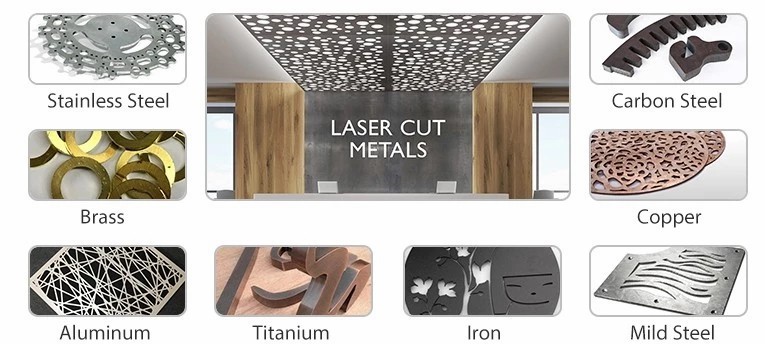

Materiae Applicationis:

Lamina Chalybis Inoxidabilis, Lamina Chalybis Lenis, Lamina Chalybis Carbonis, Lamina Chalybis Mixti, Lamina Chalybis Vernalis, Lamina Ferrea, Ferrum Galvanizatum, Lamina Galvanizata, Lamina Aluminii, Lamina Cuprea, Lamina Aeris, Lamina Aenea, Lamina Aurea, Lamina Argentea, Lamina Titanii, Lamina Metallica, Lamina Metallica, Tubi et Fistulae, etc.

Exempla

Commodum

1. Secandum subtiliter, usque ad 0.05-0.1mm. Utere gaso auxiliari apto, ut fissurae nitidae et leves sint, politura secundaria non necessaria.

2. Caput secans automatice intendit. Sensore capacitivo importato celeriter progressum adhibens, altitudinem laminae dynamicam perpetuo sequendo. Altitudinem secandi automatice adaptando, quae collisionem impedit, laminam inaequalem secare potes.

3. Machina secans motorem servo importatum adhibet, modulum linearem importatum summae praecisionis, celeritatem, altam praecisionem usque ad 0.01mm. Longa vita utilis.

4. Laseribus fibrae provectis utuntur, instrumenta principalia importata. Alta stabilitas, longa vita, nullis subsidiis, sine cura.

5. Designatio professionalis instrumenti ad pulverem auri recuperandum, pulvis et pulvis omnem instrumentum recuperationis collegit. Ita damnum ad minimum redigitur.

6. Pro industria aurea et argentea gemmarum, systemate secandi laseris professionali ad usum consuetum, cum optimizatione semitae, optimizatione puncti initialis secandi, multi-strato, functione dispositionis, tempore et materia conservando.

7. Magnitudo parva, energiae consumptio humilis, copiae pauciores, sustentatio facilis. Aere compresso etiam secari potest, sumptus humilis.